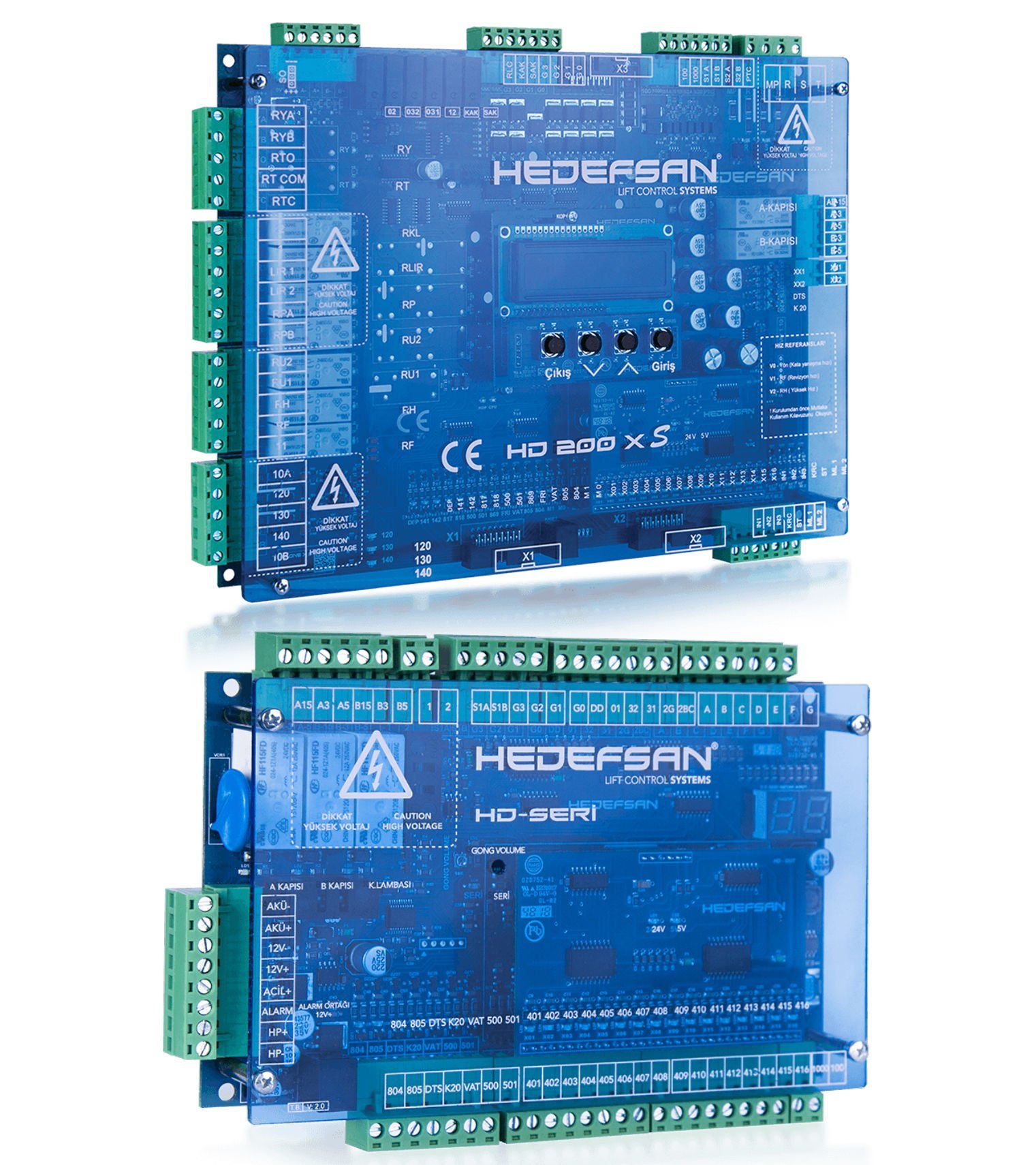

HD 200 X-S SET

0 Point - 0 Comment

Category

Brand

Stock Code

9HEDEFSAN/HD-ST022111

Discount Rate

37 %

Discounted Price

163,80 USD

%37

Discount

260,00 USD

163,80 USD

PACKAGE CONTENTS

1 Unit HD 200 X S Main Board

1 Unit HD 200 X S Serial Board

1 Unit 200 X S Terminal Board

3 Units Flat Cable

Mounting Parts

- Can operate simple and cumulative control for up to 16 stops

- Call lamps and buttons can be connected to the system using just one cable

- All parameters can be easily adjusted using the LCD screen and programming buttons on the board

- Password-protected programming, PUK code protection against unauthorized use

- The last 16 errors; stops, direction, date, and time information can be monitored from the LCD screen

- In standby mode, the LCD screen can show how long (days, hours) the elevator has been in operation since the last maintenance

- Adjustable maintenance duration, with a warning on the LCD screen when the maintenance duration has expired

- Simple and error-free installation thanks to the internal terminal board, saving time and space on control panel terminals

- Overload function

- Short circuit protected, adjustable display outputs for each stop

- Display outputs can be converted to gray code or binary output

- Direction indicators, out-of-service signal, and busy signal with relay contact outputs; signal partner input for these outputs

- Adjustable parking stop and parking time

- Counter bi-stable switch input for position information

- Option to take the cabin to the first stop upon initial power-up

- Warning function on the LCD screen when the door has been open for a long time or when the stop reversal circuit cannot be detected for a long time

- Adjustable cabin light duration, lock waiting time, waiting time at the floor, maximum high-speed duration, and maximum low-speed duration

- Door opening signal (AUTO) and selection of how this signal operates based on direction indicators

- Manual movement at slow speed using programming buttons

- Option to display the first stop the cabin will go to at each floor change

- Option to move the cabin to the limit switches or floor alignment during revisions

- Selection of the floor with the fully automatic door for elevators with only one fully automatic door

- Electronic phase, phase sequence, and PTC (Motor temperature) control; display of errors related to these controls on the LCD screen, with the ability to disable these functions through parameter selection, and adjustment of phase level sensitivity

Be the first to comment on this product!